Alumina Ceramics

High-Purity Alumina Ceramics

Applied Ceramics is a trusted high alumina ceramic manufacturer providing custom components made of 99.5% and 99.8% aluminum oxide. Clients choose ACI-995 & ACI-998 for their superior thermal conductivity, electrical insulation, & mechanical strength properties.

What is Alumina Ceramic?

Alumina ceramic, sometimes referred to as simply ‘alumina’ or aluminum oxide (Al₂O₃), is a high-performance technical ceramic best known for its hardness, corrosion resistance, and insulation properties. This versatile material is popular in a wide range of applications related to semiconductors, autos, medical devices, and more.

-

Alumina Ceramics

Properties Units 99.5% Aluminum Oxide 99.8% Aluminum Oxide MECHANICAL Density gram/cm3 3.8-3.9 3.9 Color – ivory/white ivory Water Absorption % 0 0 Flexural Strength MPa@room temp.(R.T.) 310-379 400 Compressive Strength MPa@R.T. 2070-2620 3180 Hardness GPa 13.8-17.6 14.0-15.0 THERMAL Coefficient of Linear

Thermal Expansion1E-6/°C

(»25°C to Ј1000°C)9.0-9.4 8.0 Thermal Conductivity W/m°K@R.T. 25.1-35.6 29.5 Specific Heat cal/g°C@R.T. 0.19-0.21 0.21 Thermal Shock Resistance D T(°C) 200 250 Maximum Use Temperature °C 1600-1750 1800 ELECTRICAL Volume Resistivity Ohm. cm@R.T. >1014 >1014 Dielectric Constant 1MHz@R.T. 9.6-10.2 9.8

Custom Aluminum Oxide Applications

Our custom alumina ceramics are typically used in:

- Semiconductor equipment (substrates, laser components)

- Automotive sensors & insulators

- Medical devices

- Oil & Gas energy processing

- Military defense & armor systems

- Precision electronics

Alumina Ceramic Main Properties

- Molecular Formula: Al₂O₃

- Molecular Weight of Alumina: ~101.96 g/mol

Weight 99.5% Alumina Ceramic (ACI-995)

ACI-995 is a versatile aluminum oxide ceramic material ideal for:

- Ceramic-to-metal feedthroughs requiring hermetic seals (vacuum-tightness)

- Thermal test instrumentation

- Gas laser tubes

- Circuit board substrates

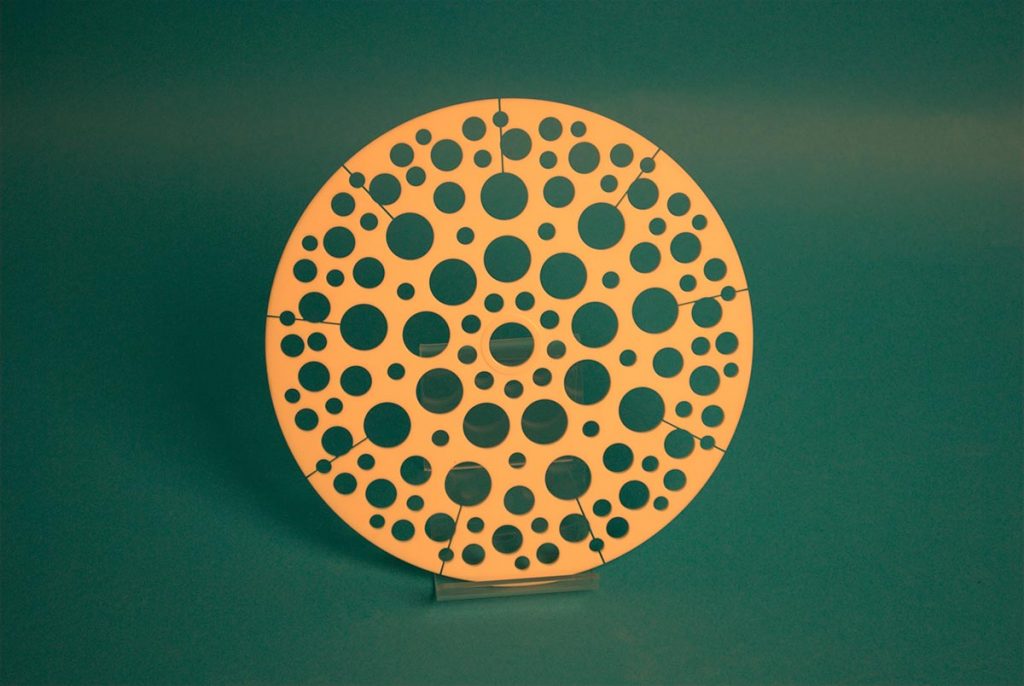

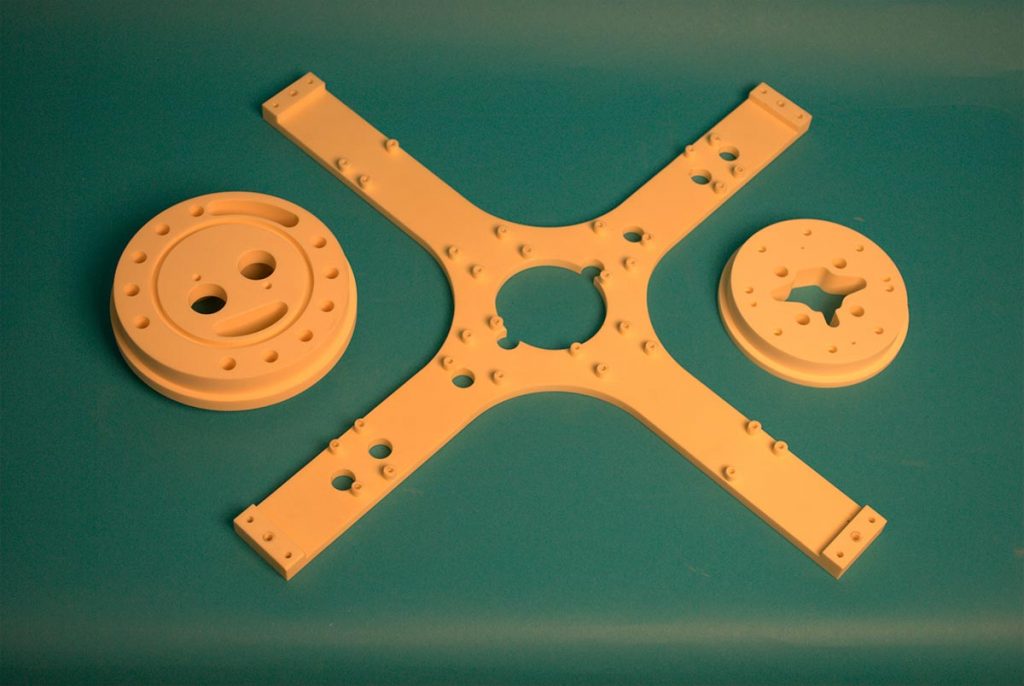

Applied Ceramics manufactures its 99.5% Alumina into different shapes depending on a client’s intended application. These include disks, rings, rectangles, and custom shapes that offer excellent wear resistance, shock resistance, and electrical insulation.

With over 20 years of experience in Alumina ceramic manufacturing, the ultra-precision custom parts made from Applied Ceramics’ ACI-995 Alumina consistently meet the most formidable demands.

Please contact our experts for full product specifications, manufacturing details, and to request a quote from one of our outstanding customer service representatives.

Looking for 99.8% weight aluminum oxide (ACI-998)? We also offer this higher purity option for premium applications.

Weight 99.8% Alumina Ceramic (ACI-998)

ACI-998 is the most popular technical high alumina ceramic we offer. Our premium aluminum oxide, boasting 99.8% purity, offers enhanced performance for:

- Ultra-precise components

- High-voltage insulation

- Corrosive environments

The combination of low thermal expansion, high dielectric strength, & excellent mechanical properties makes ACI-998 an ideal material for the most demanding of applications.

Frequently Asked Questions About Alumina

Is Alumina a Ceramic?

Yes, alumina (Al₂O₃) is a technical ceramic best known for its strength and insulation properties, among other desirable traits, making it a versatile material.

Is Alumina Ceramic Safe?

Yes, ACI-995 & ACI-998 are both considered safe for industrial and commercial use. Alumina ceramic is non-toxic, chemically inert, & corrosion resistant which makes it an ideal material for use in medical devices, personal electronics, & food processing equipment.

What Properties Does Alumina Have?

Alumina ceramic has a range of valuable properties that make it ideal for demanding applications in electronics, automotive, & medical industries. These properties include:

- High hardness & wear resistance

- Excellent electrical insulation

- Strong thermal conductivity

- Corrosion resistance to acids & alkalis

- Low coefficient of thermal expansion

What is the Purity of Alumina Ceramics?

Alumina ceramics are available in various purities that often range from 80% to 99.9% aluminum oxide. Applied Ceramics offers ACI-995 with 99.5% purity and ACI-998 with 99.8% purity. Our premium ACI-998 offers improved electrical insulation, thermal stability, & mechanical strength for more demanding applications.

What are the Disadvantages of Alumina?

While its many valuable properties serve as advantages to using alumina ceramics in your applications, like all materials, there are a few disadvantages to consider as well:

- Brittleness – as with most ceramics, alumina is susceptible to fracturing under high impact or tensile strength.

- Difficult to Machine – while advantageous in applications, the material’s high hardness requires specialized equipment that can wear & fracture frequently. Applied Ceramics has both the advanced equipment and decades of experience needed to machine aluminum oxide into complex, high-tolerance shapes.

- Limited Thermal Shock Resistance – while alumina ceramics can handle moderate thermal cycling, the material may crack in an environment with extreme, rapid temperature fluctuations.

Request a Quote for Custom Alumina Ceramic Parts Today

Let our experts help you choose the right alumina ceramic material for your applications. Please fill out the form below for a free custom alumina ceramics quote.